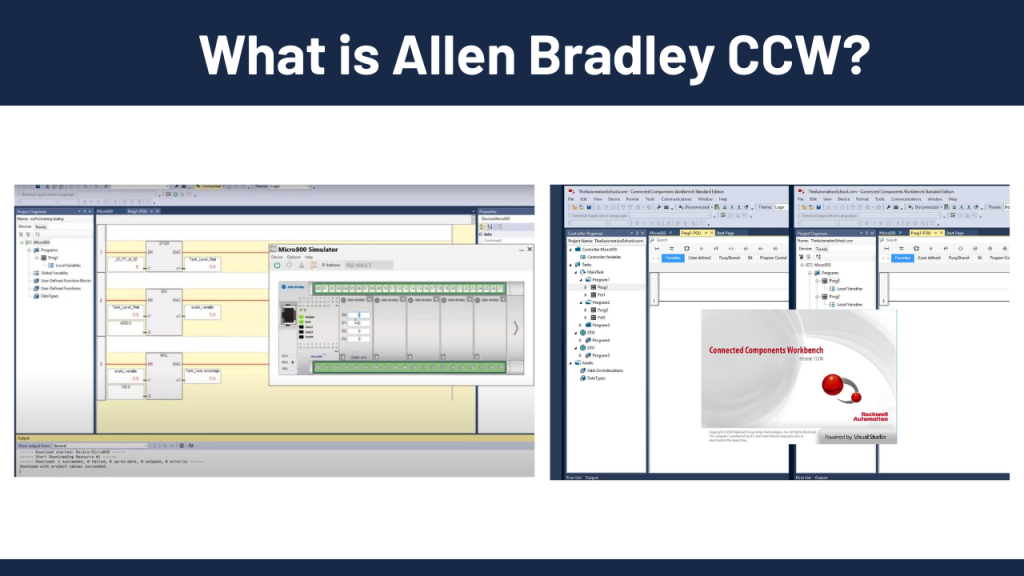

What is Allen Bradley CCW?

Linked Parts Rockwell Automation CCW created the Workbench software suite to simplify the configuration and design of control systems. It can be used for a wide range of tasks, from straightforward standalone machines to intricate industrial processes. CCW is a component of Rockwell’s Connected Enterprise, an ecosystem that combines information and control to provide easy communication between departments inside a company.

1.User-Friendly Interface:

The software is easy to use and navigate for both novices and seasoned experts thanks to CCW’s user-friendly design. The ability to drag and drop elements makes control logic creation easier and more approachable for a wider range of users.

Device Configuration: CCW allows users to easily setup and program controllers, Human Machine Interfaces (HMIs), and other components. It supports a wide range of Rockwell Automation devices. By offering a single platform for device configuration, the program lessens the hassle of juggling several tools.

2.Programming Capabilities:

The adaptability of CCW’s programming is one of its advantages. It works with ladder logic, structured text, and function block diagrams among other programming languages. Because of this versatility, users can select the programming language that best suits their level of experience and the particular needs of their automation projects.

A popular graphical programming language for industrial automation is called Ladder Logic. Ladder logic diagrams, which are similar to electrical relay logic diagrams, can be created with CCW. Engineers, particularly those with an electrical engineering background, find it easier to create and comprehend the control logic using this visual depiction.

3.Simulation and Emulation:

Before implementing their control logic in a real setting, users can test it using the simulation and emulation tools included with CCW. This lessens the requirement for actual prototypes, which speeds up development while also aiding in the identification of any problems.

- Overview: The virtual execution of the designed control logic in a simulated environment is known as simulation in CCW. Without requiring actual hardware, it allows engineers to see how the control system would operate.

- Virtual Components: The virtual execution of the designed control logic in a simulated environment is known as simulation in CCW. Without requiring actual hardware, it allows engineers to see how the control system would operate.

- Real-Time Monitoring: Engineers are able to watch in real time as the control logic behaves during simulation. This entails keeping an eye on the values of input and output, variables, and the way that programs are being executed.

- Identification of Issues: Prior to the control logic being applied to the real hardware, simulation aids in the detection of possible problems such as timing irregularities, logical mistakes, or unexpected behavior.

Check :- Allen Bradley Micro820 Programmable Controller

4.Integrated Motion Control:

CCW offers integrated tools for configuring and programming motion axes in motion control applications. This functionality is especially helpful in situations where having exact control over how machines or processes move is essential.

5.Remote Monitoring and Troubleshooting:

With the help of the Connected Components Workbench, engineers can monitor and troubleshoot problems remotely from a single location. This feature reduces downtime and improves the overall effectiveness of maintenance tasks.

Benefits of Using CCW:

Increased Efficiency:

By giving developers access to a single platform for configuration and programming, CCW speeds up development. The more efficient design and implementation of control systems are facilitated by the streamlined process and user-friendly interface.

Cost Savings:

Costs are saved throughout the development stage since fewer actual prototypes are required thanks to CCW’s simulation and emulation characteristics. Furthermore, the ability to monitor remotely reduces downtime and enhances overall cost-effectiveness.

Flexibility and Scalability:

CCW is a scalable and versatile solution since it supports a broad variety of Rockwell Automation devices and numerous programming languages. It can adjust to changing automation requirements and meet the needs of different sectors.

Enhanced Collaboration:

As a component of the Connected Enterprise, CCW fosters cooperation by offering a shared control and information platform. This integration facilitates smooth communication between various organizational levels, which enhances operational effectiveness and decision-making.

Robust Security Measures:

Rockwell Automation places a high priority on product security, and CCW is no different. The software ensures the dependability and security of industrial operations by incorporating strong security mechanisms to guard control systems against any cyber threats.

The Connected Components Workbench from Rockwell Automation is an effective tool that makes a big difference in the development of industrial automation. Engineers and other experts engaged in the construction and upkeep of control systems turn to it because of its intuitive interface, flexible programming options, and array of features. CCW is a dependable and effective partner for industries that are constantly changing, enabling businesses to increase productivity and competitiveness in the automation market.

Asteam Techno Solutions Pvt. Ltd. has boasts over 10 years of experience in the industrial sector, founded in India and then became one of the best industrial automation parts supplier in India as well as globally. We provide automation solutions with reputed brands including Allen Bradley, Mitsubishi, Phoenix Contact, Siemens, Schneider, Moxa, VIPA and more.